Detecting electrical problems early can prevent minor inconveniences from escalating into significant disruptions or hazards. Knowing the key indicators of electrical issues is the first step in proactive maintenance, so read on to learn how to detect electrical problems in your systems.

Key Takeaways

- Knowing the signs and identifying electrical problems early are key to keeping significant issues at bay.

- Common electrical issues in industrial settings include overloaded circuits, outdated wiring, and disorganized systems.

- Preventative measures like frequent electrical inspections can identify and stop problems at their source.

Indicators of Electrical Problems

If you have an electrical issue, it’s best to detect it as early as possible. Fortunately, there are several warning signs that can alert you to problems before your system suffers a major failure. Below are a few common indicators to watch out for:

Flickering or Dimming Lights

Flickering or dimming lights is one of the most noticeable signs of electrical trouble. This phenomenon can come from fluctuations in the power supply, loose wiring connections, or overloaded circuits. In an industrial setting, where lighting is critical for safety and productivity, consistent dimming or flickering can hinder operations and signal deeper electrical concerns that need immediate attention.

Frequent Tripping of Circuit Breakers

Circuit breakers protect electrical circuits from damage caused by overload or short circuits. If breakers trip frequently, it indicates excessive electrical demand or underlying wiring issues. Persistent tripping can disrupt operations and may be a precursor to more severe electrical failures or fire risks.

Unusual Odors, Such as Burning Smells

A burning smell from electrical fixtures, outlets, or equipment is a warning sign. It often indicates overheating components, such as wires or circuit breakers, which can lead to electrical fires if not addressed promptly. If you think you’re smelling something from your electrical system, don’t wait to get it checked out!

Warm or Discolored Outlets and Switches

Outlets and switches that feel warm to the touch or are discolored can indicate excessive electrical resistance or poor connections. These conditions make systems less efficient and increase the risk of electrical fires. To mitigate these hazards, immediate inspection and repair are necessary.

Unexplained Equipment Malfunctions

When electrical equipment malfunctions without an apparent cause, it may be due to inconsistent power supply, voltage fluctuations, or internal wiring issues. These malfunctions can lead to costly downtime, reduced productivity, and potential damage to sensitive machinery, highlighting the need for thorough electrical diagnostics.

Common Electrical Challenges and Their Remedies

Understanding significant electrical challenges in commercial and industrial environments allows you to implement practical solutions, ensuring seamless operations and enhanced safety.

In this section, we’ll discuss some common challenges you might encounter and the best solutions for these issues.

Overloaded Circuits

Overloaded circuits happen when too many devices or machinery are connected to a single electrical circuit, exceeding its capacity. This excessive load can cause wires to overheat, increasing the risk of fires and reducing the lifespan of electrical components.

Solution: Distribute electrical loads evenly across multiple circuits to address overloaded circuits. You can identify high-demand areas and allocate additional circuits to accommodate the electrical load. In cases where the existing electrical panel cannot support the increased demand, you may need to upgrade to a higher-capacity panel. This not only prevents overheating but also enhances the overall reliability of the electrical system.

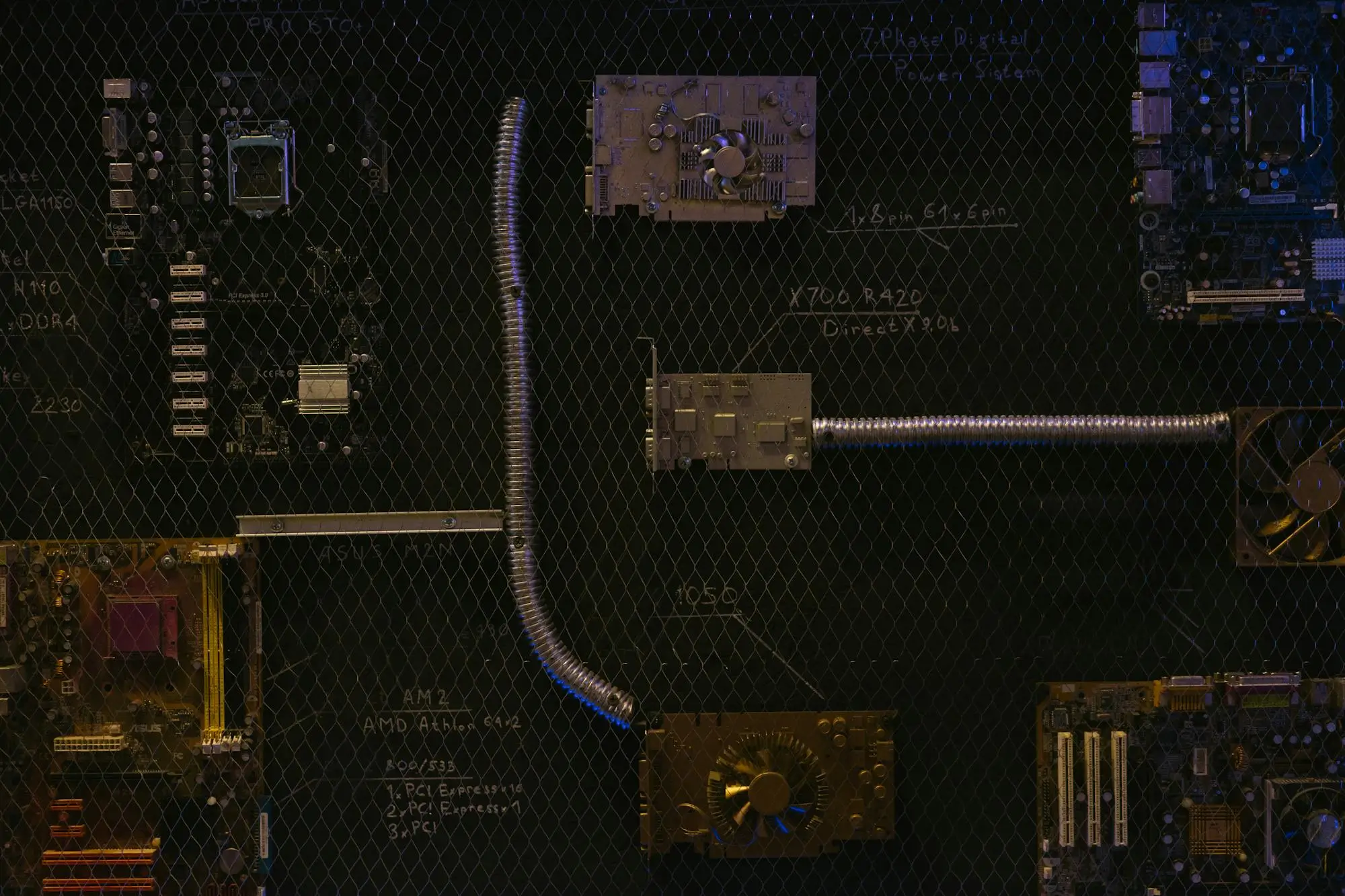

Disorganized or Mislabeled Electrical Panels

Electrical panels that are cluttered or incorrectly labeled pose significant safety risks and can lead to confusion during maintenance or emergencies. Inaccurate labeling also makes identifying and isolating specific circuits difficult, prolonging downtime and complicating repairs.

Solution: Maintaining organized and clearly labeled electrical panels is crucial for efficient electrical management. Each circuit breaker should be accurately labeled to reflect the area or equipment it controls. It’s a good idea to conduct regular audits and updates to the labeling system to ensure that it remains accurate. Additionally, organizing the panel to minimize clutter and clearly separating different circuits enhances safety and facilitates quick identification during troubleshooting.

Outdated or Faulty Wiring

Aging or damaged wiring is common in older commercial and industrial buildings. Over time, insulation can degrade, and wires can become brittle or corroded, leading to short circuits, voltage drops, and increased fire hazards. Faulty wiring can compromise the integrity of the entire electrical system, affecting safety and operational efficiency.

Solution: Regular electrical inspections are essential to identify wear and tear in the wiring system. Facilities should prioritize replacing outdated or damaged wires to comply with safety standards and prevent potential hazards. Investing in modern wiring materials and adhering to best practices during installation can significantly enhance the durability and safety of the electrical infrastructure.

Insufficient Outlets

You’ll rely on extension cords and power strips to power various devices and machinery without adequate electrical outlets. This overreliance increases the risk of electrical fires, tripping hazards, and equipment damage due to inconsistent power supply.

Solution: Thoroughly assessing your facility’s power requirements is vital to mitigate the risks of insufficient outlets. Installing additional outlets in strategic locations ensures that devices can be connected directly to the electrical system, reducing the need for extension cords. This enhances safety and supports a more organized and efficient workspace.

Grounding Issues

Proper grounding is essential for the safe operation of electrical systems. Improper grounding can lead to electrical shocks, equipment damage, and increased susceptibility to electrical noise, affecting sensitive machinery. Grounding issues compromise the safety and functionality of electrical equipment.

Solution: To ensure proper grounding, verify that all electrical systems are correctly connected to the grounding infrastructure. Regular testing and maintenance of grounding systems help safely dissipate excess electricity, prevent electrical shocks, and safeguard equipment.

Be sure to find qualified electricians to assess and fix grounding issues; this will ensure compliance with safety standards and reduce the risk of electrical hazards.

Improper Installation of Hardwired Equipment

Hardwired equipment, such as industrial machinery, HVAC systems, and specialized appliances, require precise installation to function safely and effectively. Incorrect installation can lead to malfunctions, reduced efficiency, and safety hazards, including electrical fires and equipment damage.

Solution: Choosing qualified and experienced professionals to install hardwire is crucial. Certified electricians ensure that installations comply with industry standards and safety regulations.

Proper installation enhances performance and longevity while minimizing the risk of electrical issues that could disrupt operations or endanger employees.

Loose or Exposed Electric Connections

Loose or exposed electrical connections are a significant fire hazard, as they can cause arcing and overheating. These unsecured connections jeopardize the facility’s safety and lead to inconsistent power supply, affecting the performance of electrical equipment.

Solution: It is essential to inspect all electrical connections regularly for signs of looseness or exposure. Securing connections and ensuring they are adequately insulated prevents arcing and overheating. Implementing a maintenance schedule that includes checking and tightening connections helps maintain the electrical system’s integrity and reduces the risk of fire hazards.

Preventative Measures and Best Practices

Proactive measures and adherence to best practices are critical in preventing electrical issues and ensuring the longevity and safety of electrical systems in commercial and industrial environments.

Regular Electrical Inspections

Schedule routine inspections to identify and address potential issues before they escalate.

Regular electrical inspections are the cornerstone of a safe and reliable electrical system. Qualified electricians should conduct these inspections to identify early signs of wear, damage, or non-compliance with safety standards. By addressing issues promptly, businesses can prevent unexpected downtime, reduce maintenance costs, and enhance the facility’s overall safety.

Employee Training

Educate staff on recognizing early signs of electrical problems and promptly reporting them.

Employees are often the first line of defense when identifying electrical issues. Training on recognizing common electrical problems, such as flickering lights or unusual odors, empowers staff to report concerns before they escalate. Training should also cover basic electrical safety practices, emergency procedures, and the importance of not tampering with electrical components without proper authorization.

Upgrading Electrical Systems

Modernize outdated systems to handle current power demands and enhance safety.

As businesses grow and technology advances, you’ll want to update electrical systems to accommodate increased power demands and incorporate the latest safety features. Upgrading electrical panels, installing energy-efficient wiring, and integrating smart electrical management systems can improve reliability and reduce the risk of electrical failures. Investing in modern electrical infrastructure supports current operational needs and prepares your facility for future expansions and technological advancements.

Implementing Surge Protection

Install surge protectors to safeguard equipment from voltage spikes.

Voltage spikes, often caused by lightning strikes or power surges, can damage sensitive electrical equipment and disrupt operations. To ensure comprehensive protection against electrical surges, surge protection devices (SPDs) should be strategically placed at key points in the electrical system, including main panels and individual equipment connections. SPDs help absorb and dissipate excess voltage, protecting machinery and data.

Ensuring Compliance with Electrical Codes

Adhere to local and national electrical codes to maintain safety and legal compliance.

Compliance with electrical codes and regulations is a legal requirement and critical to maintaining a safe working environment. Electrical codes are regularly updated to incorporate new safety standards and technological advancements. Ensuring that all electrical installations and maintenance practices adhere to these codes minimizes the risk of accidents, fines, and operational disruptions. Regular audits and staying informed about code changes are essential for maintaining compliance.

Conclusion

Maintaining a robust and reliable electrical system in commercial and industrial environments is a multifaceted endeavor that requires vigilance, expertise, and proactive management. By recognizing the indicators of electrical issues, understanding common challenges and their remedies, and implementing preventative measures and best practices, business owners and facility managers can safeguard their operations against electrical disruptions and hazards. Investing in regular inspections, employee training, system upgrades, surge protection, and compliance with electrical codes not only enhances safety but also contributes to the overall efficiency and sustainability of the business.

If you are experiencing occurrences that suggest an electrical issue in your industrial or commercial building, or you simply want peace of mind in your systems, our expert team of electricians at Sidney Electric is happy to help. Contact us for a consultation or quote. We look forward to providing you with top-notch service, allowing you to focus on core operations without worrying about electrical failures.